Mobile column - EHB907V11AC Cabled

EHB907V11AC Cabled

article no.: EHB907V11AC01-M/S

|

Technical data sheet:

Download

Product variants

Mobile columns EHB90XV11AC with a capacity of 7.5 t each cover a variety of different commercial vehicles, e.g. buses and trucks (wheel diameter 550 - 1140 mm). The columns are powered by a supply unit that is connected to the mains. They have a low-maintenance hydraulic drive and communicate via radio. Operation is possible via a clear LCD display on each column. Up to 10 columns can be combined into one lifting system or divided into several smaller systems if required. Examples of the configuration of a lifting system:

- Set of 4: 1 x EHB907V11AC01-M plus 3 x EHB907V11AC01-S

- Set of 6: 1 x EHB907V11AC01-M plus 5 x EHB907V11AC01-S

- Set of 8: 2 x EHB907V11AC01-M plus 6 x EHB907V11AC01-S

product images

accessories

EHB907TDH

hydraulic pallet jack

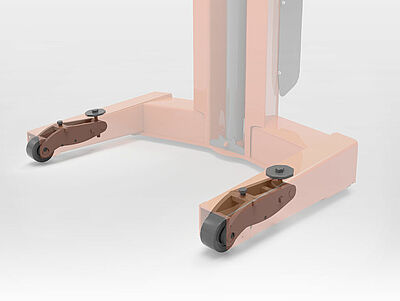

EHB907TDA

front wheels height adjustable

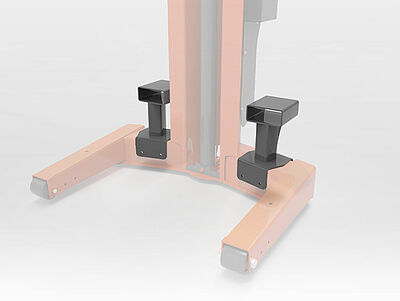

EHB907FLP

Forklift pockets

EHB907-LS-PR503-385

Load support,

pluggable

pluggable

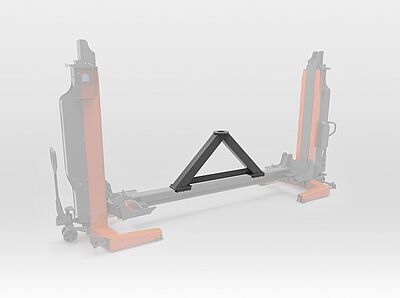

EHB907TRT412TR01-385

Basic cross beam 880 mm,

tractor support at front

tractor support at front

EHB907TRT412TR02-385

Basic cross beam 640 mm

tractor support at rear

tractor support at rear

EHB907TR17

Truck crossbeam, 17 t,

length 3000 mm

length 3000 mm

EHB905TR113000

Crossbeam, 11 t,

length 3000 mm

length 3000 mm

EHB907TA17

Trailer-support

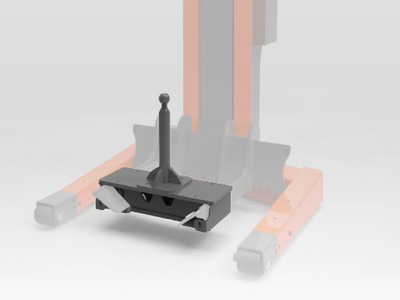

EHB907BCS

Support for ball coupling

EHB907SPOT02

2 LED spots

MS08LR

support stand, 8.2 t,

790-1270 mm

790-1270 mm

HS08LR

support stand, 8.2 t,

1260-1990 mm

1260-1990 mm

GB1502010FVSVLR

support stand, 15 t,

1390-2075 mm

1390-2075 mm

RW1300000

wheel carriage, 500 kg,

stroke 1600 mm, Ø500-1800 mm

stroke 1600 mm, Ø500-1800 mm

your system benefits

Versatile use in the workshop

The existing workshop area remains free for various use. You take the mobile columns to just where you need them, indoors or outdoors. Thus the hoists of model EHB can be used most versatile and multi-functional.

Free access to the vehicle

Have fun to get your work done! With free access to the underside of the raised vehicle; with sufficient head clearance by large lifting height; with best lighting conditions underneath the vehicle which can even be improved using LED spotlights; with efficient working at floor level and short distances to walk; with your portable workshop equipment such as transmission jacks, tool boxes etc. easily maneuvered directly underneath the vehicle; with axle stands to support the vehicle for free access to wheels and brakes.

Safe support of the vehicle

The lift columns are moved towards the vehicle and positioned at the wheels, quickly and simply. The wheel forks can be adjusted in order to touch the wheels from both sides and to secure the load.

Economic efficiency

Nonstationary and movable vehicle lifts do not require expensive foundations works or a permanent installation. Just a standard even workshop floor is sufficient to operate the lift.

In comparison to all other workshop systems such as pits, in-ground or stationary platform lifts mobile columns by far represent the most economic workshop solution.

Within the workshop area any number of column sets can be operated.

technical specifications

specifications

| article no. | EHB907V11AC01-M/S | |

| lifting unit | type of columns | all columns identical |

| quantity of columns | 1 | |

| quantity of columns, maximum | 10 | |

| load support | load support | adjustable wheel fork |

| capacity per column | 7.5 t | |

| wheel size Ø minimum (mm) | 550 mm | |

| wheel size Ø maximum (mm) | 1140 mm | |

| length of fork (mm) | 385 mm | |

| height | lifting stroke effective | 1750 mm |

| lifting height | 1850 mm | |

| frame height at front (mm) | 100 mm | |

| speed | lifting time | 90 sec. |

| lowering time (under load) | 90 sec. | |

| drive | mode of drive | electro-hydraulic |

| motor | Three phase alternating current | |

| motor power per column (kW) | 2.2 KW | |

| power supply | electrical connection per column | 400V/3Ph+N+PE/50Hz |

| communication | communication via radio, wireless | |

| operation | mode of operation | operation at each column |

| activation | all, individual, axle-wise, group mode | |

| control | electronic | |

| Softstart | yes | |

| regularisation | synchronisation | proportional valves, infinitely variable |

| travelling device | travelling device | at each column |

| travelling device at front | 2 front wheels, fixed | |

| travelling device at rear | 1 wheel handle, spring-loaded, self-lowering under load | |

| ground clearance at front | 15 mm | |

| ground clearance at rear | 35 mm | |

| load securing | load securing | hydraulic and mechanical |

| dimensions | length | 1200 mm |

| width | 1165 mm | |

| height | 2255 mm | |

| height of fork (mm) | 100 mm | |

| weight | weight per column (kgs) | 540 kg |

| protection class | IP54 | |

| surface treatment | type of surface treatment | powder coating |

| colour | orange RAL2004 / grey RAL7015 |